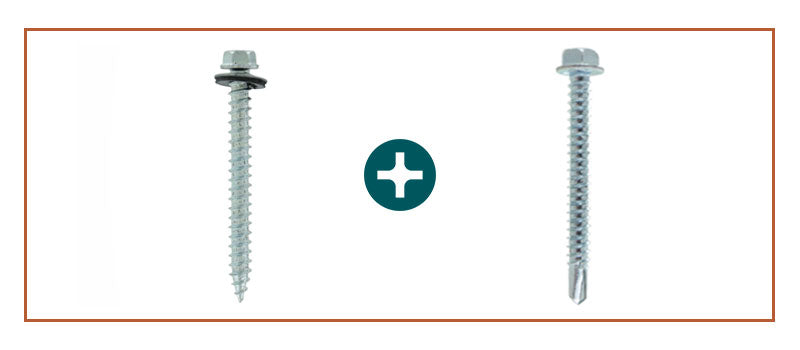

Self Tapping vs. Self Drilling Screws

Self-tapping screws and self-drilling screws are often confused with each other. Both of these screw types are commonly used in construction, commercial, and industrial applications. Continue reading to learn what self-tapping and self-drilling screws are, the applications they are designed for, and the differences between these fasteners.

Differences Between Self-Tapping and Self-Drilling Screws

Before we get into the difference, it’s important to understand what tapping means when it comes to screws.

What is Tapping?

Tapping is the process of cutting threads into a material, allowing a screw to grip and hold. In most cases, tapping refers to creating internal threads in a hole, like threading the inside of a pre-drilled hole in metal or wood.

A “self-tapping” screw means it taps its own threads as it’s driven in, so no need to thread the hole manually. That’s what makes these screws convenient and fast for both pros and DIYers.

Both self-tapping and self-drilling screws are technically self-tapping because they cut their own threads. The main difference between them is the function of their points.

- The self-drilling screw can drill its own hole and the self-tapping screw cannot.

- A self-drilling screw is a favorable option when it comes to time and efficiency during installation.

- Self-drilling screws have more specialized applications than self-tapping screws.

- A noticeable difference between the screws is the tip on each screw. This is a great way to identify them from each other.

What are Self Tapping Screws?

Self-tapping screws, also referred to as tapping screws or tapper screws, require an initial pilot hole before they can be installed. However, they are designed to swiftly cut their own threads while being fastened.

What are Self Tapping Screws Used For?

Self-tapping screws are typically used to drill through thinner sheet metals and other substrates including wood and some plastics.

Tapping screws have the best performance when the punch hole is drilled to the correct size. If the hole is too big, the screw won't thread correctly and will become loose. If the hole is too small, the screw can break or cause the material to split or crack.

Common Applications Include:

- Securing one and two-layer thin gauge sheet metal

- Fastening brackets into ply and timber

- Securing aluminum sections to each other

- Screwing into plastic housing

What are Self Drilling Screws?

Self-drilling screws, also referred to as Tek screws, feature a tip that is shaped and functions similarly to a twist drill bit. The sharp point and cutting threads eliminate predrilling a pilot hole into the material. The screw cuts its threads and creates a hole in the material all in one action.

This screw design also has a notched area in the tip of the screw that receives wood chips or metal filling to create space to drill the screw all the way into the material.

For more info about self-drilling screws, check out our blog post What are Self-Drilling Screws?

What are Self Drilling Screws Used For?

Self-drilling screws are typically used on applications for quick drilling into metal-to-metal, wood-to-metal, and light-density materials.

Common Applications Include:

- HVAC applications

- Cladding and Metal Roofing

- Carports/sheds/garages

- Steel framing

- Various other general construction projects

Self-drilling screws are typically manufactured out of hardened steel and metal. The rule of thumb for using self-drilling screws is to never drill into a material that is harder than screw material. If the material is too hard, the tip of the screw will become dull and won't drill into the material.

If you use self-drilling screws to drill into very thin wood, we recommend you use a standard drill bit first to prevent splitting and cracking of the wood.