Add the Essentials

Complete your order with these essentials, compatible with:

Daggerz #8 x 2-1/4" Self-Drilling Cement Board Screw, Phillips Head - Dagger-Guard Coating, Qty. 3,000

My Cart:

Add the Essentials

Complete your order with these essentials, compatible with:

Daggerz #8 x 2-1/4" Self-Drilling Cement Board Screw, Phillips Head - Dagger-Guard Coating, Qty. 3,000

My Cart:

-

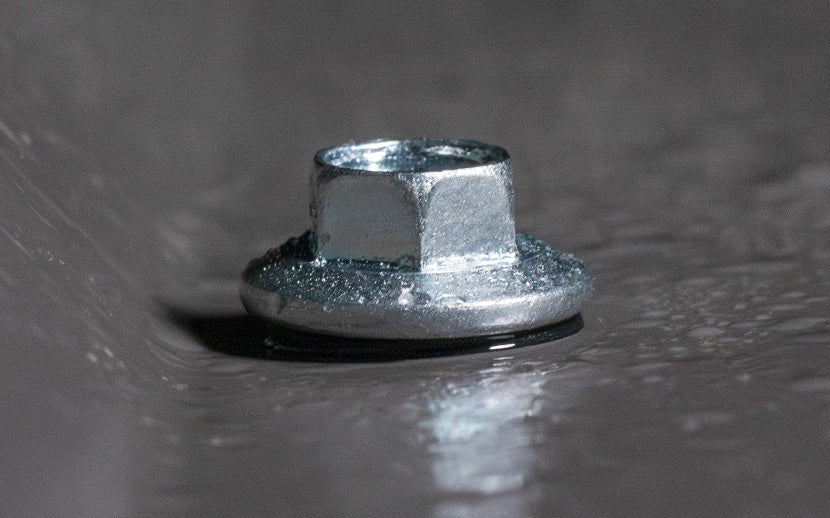

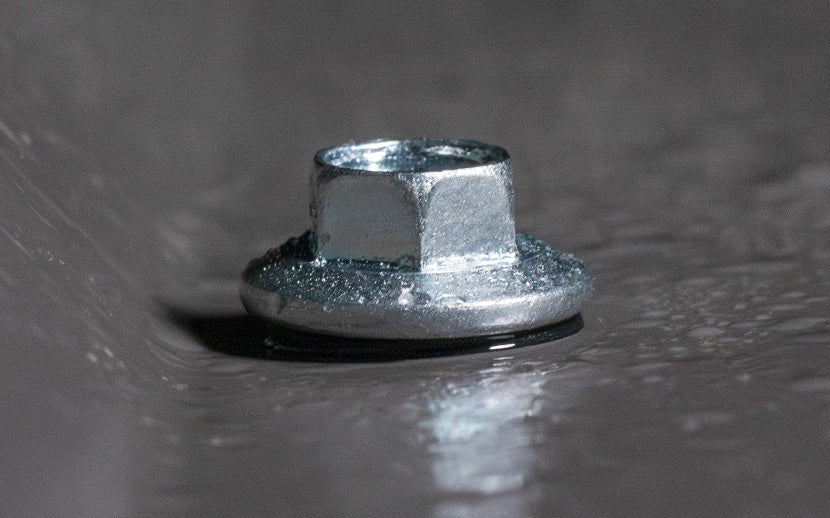

Self-Drilling Screws for Fastening Wood to Metal

These self-drilling screws feature winged tips that bore through wood and clear the path before engaging metal, ensuring clean holes and tight connections. Designed to prevent wood splitting and eliminate the need for pre-drilling, they’re ideal for framing, decking, and other wood-to-metal applications where strength and speed matter.

-

Self-Drilling Screws with Seemingly Unlimited Options

Our self-drilling screws come in a wide range of options to tackle everything from metal-to-metal and wood-to-metal fastening to interior framing and exterior cladding. Choose from multiple head styles, drive types, and corrosion-resistant finishes like zinc, galvanized, ceramic-coated, and stainless steel, each built for strength, speed, and long-term performance.

-

The Right Point for Every Project

Different point types pierce various materials. Standard points handle light- to medium-gauge metal, long points tackle thicker steel, self-piercing points work well in wood or thin metal and winged points clear softer layers before drilling harder substrates, ensuring faster, cleaner and secure installations.

-

We are on a mission to expand our national reach—offering more product selection and faster delivery times. So far we’ve made remarkable progress in our expansion efforts, effectively doubling our capacity by adding a new 47,000 sq. ft. warehouse in Simpsonville, South Carolina, in addition to our existing 60,000 sq. ft. facility in Urbana, Iowa.

-

We pride ourselves on delivering a user-friendly, high quality experience online and over the phone. Our knowledgeable team of experts is readily available via phone to assist with product questions and custom pricing inquiries. We’re available Monday thru Friday from 7:00 AM – 5:00 PM CST. We look forward to supporting you on your next job.

-

We partner with trusted manufacturers in the fasteners industry to bring our customers a selection of over 10,000 different products. Fasteners Plus is one of only four Certified Platinum E-Commerce Vendors of Simpson Strong-Tie products, one of the largest suppliers of high-quality structural building products in the world.