Add the Essentials

Complete your order with these essentials, compatible with:

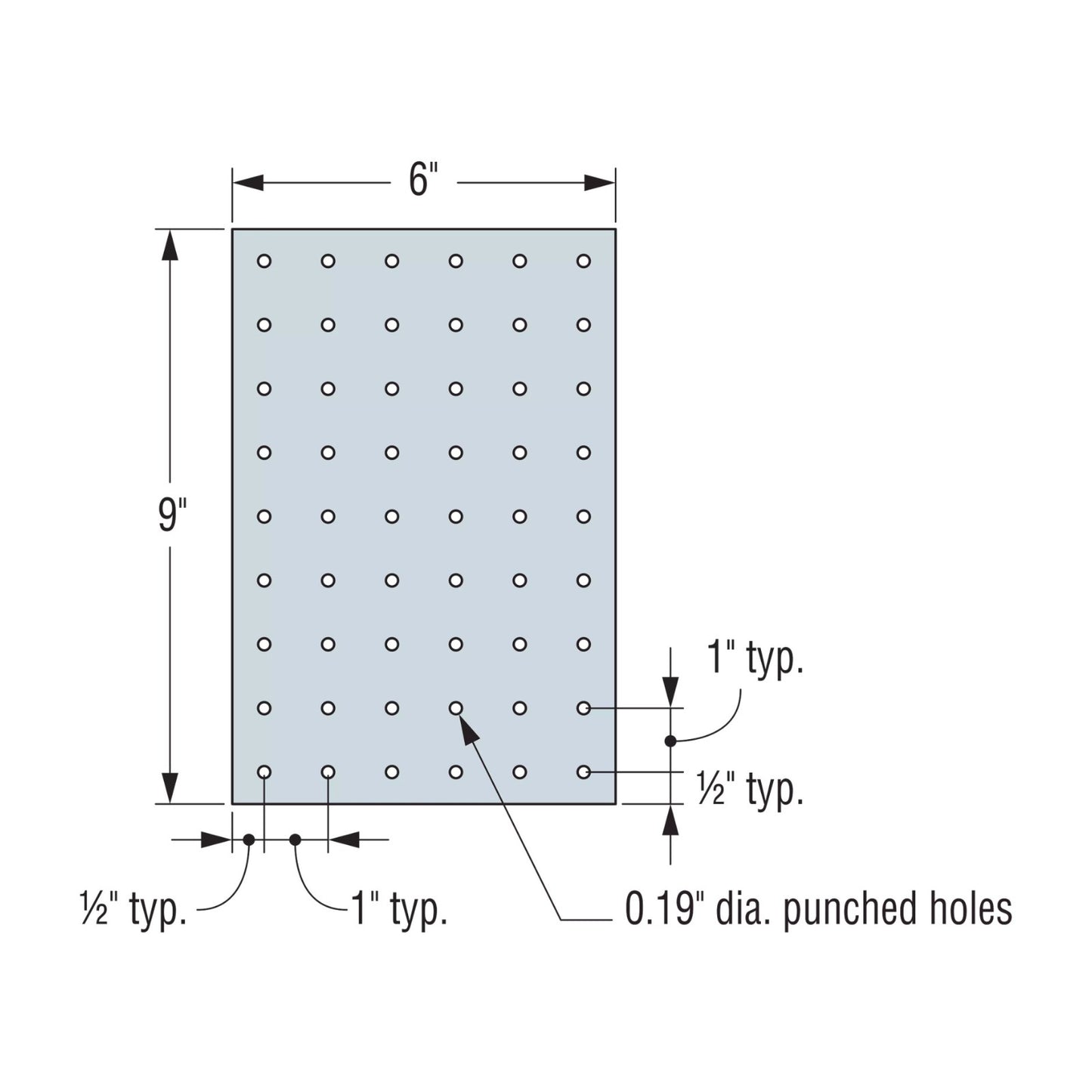

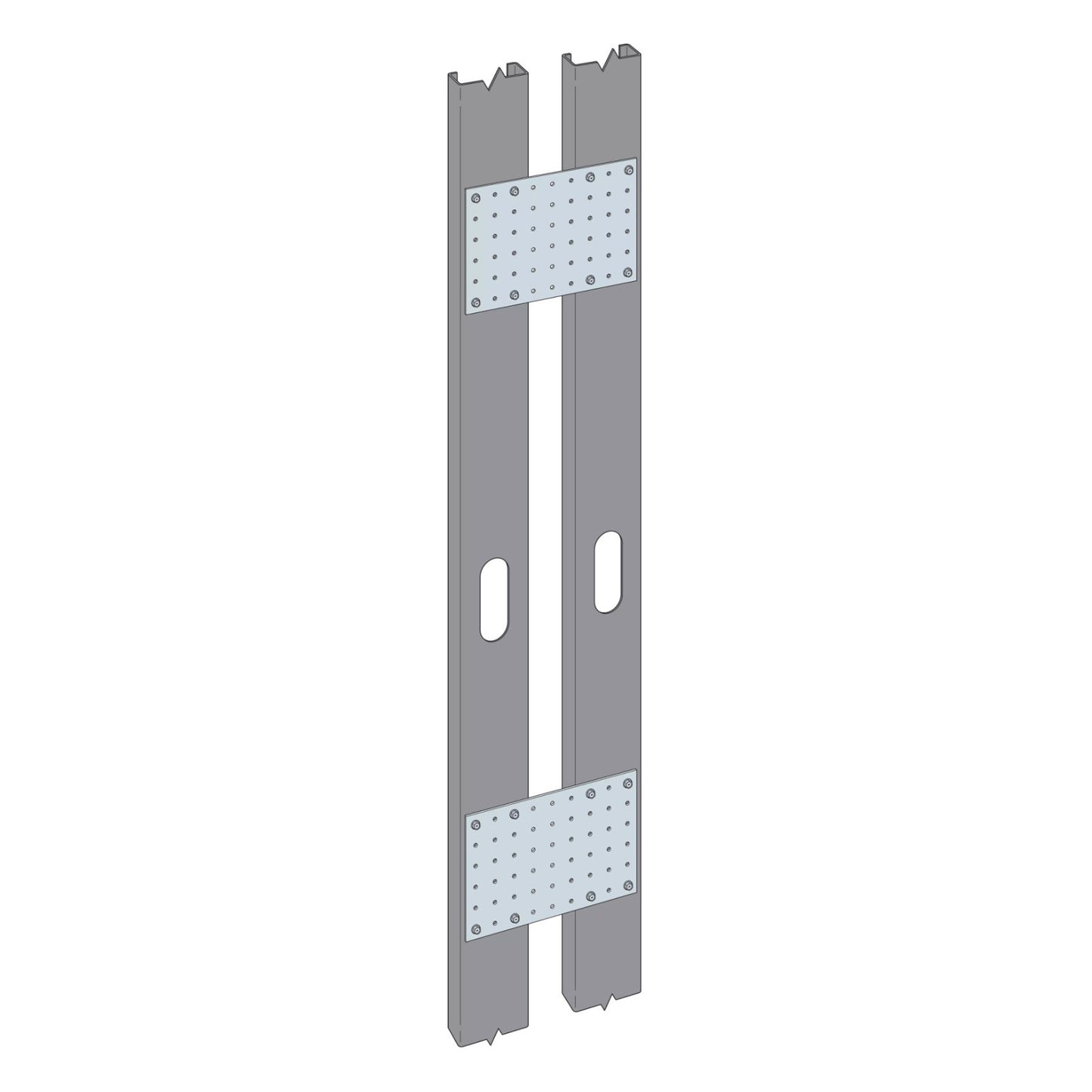

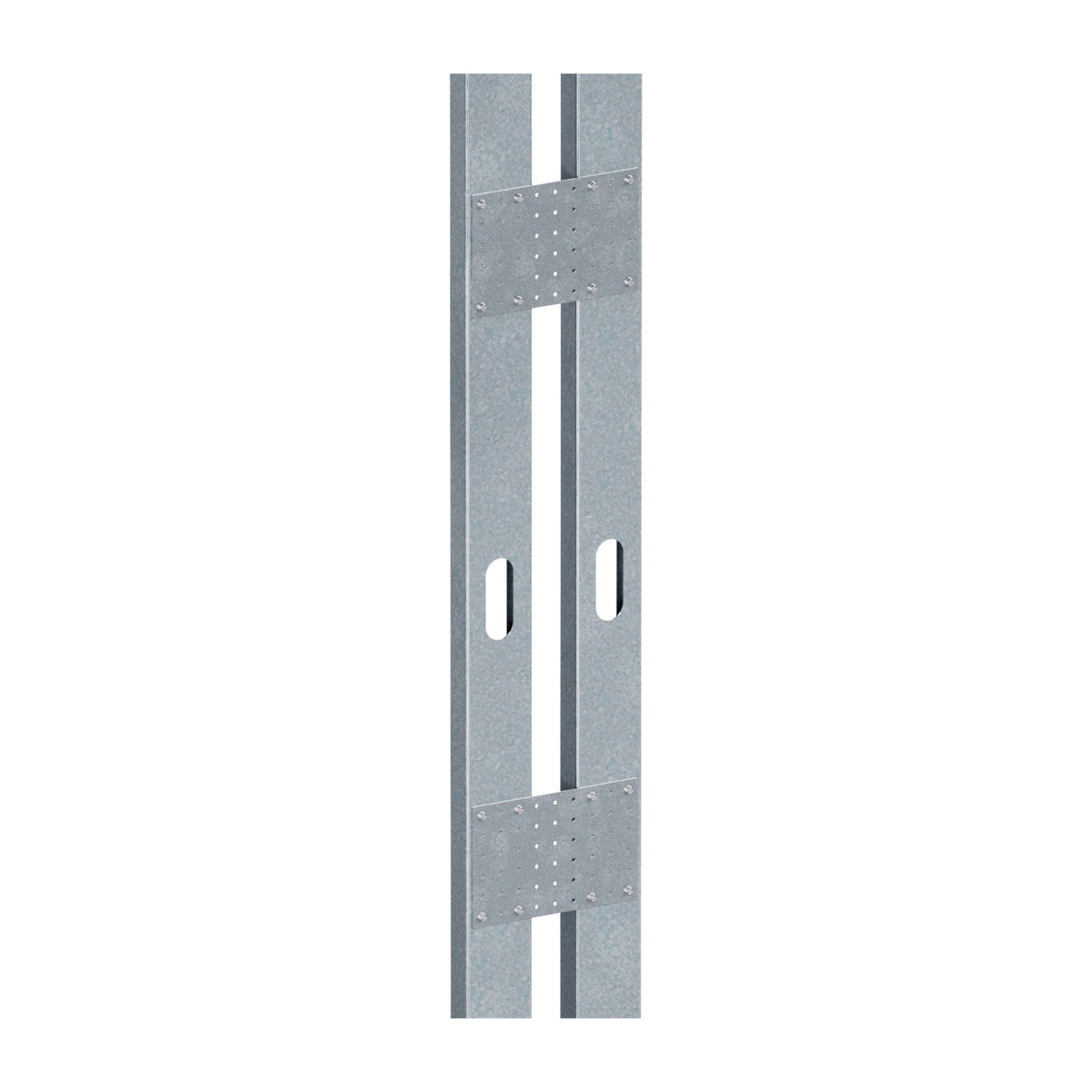

Simpson Strong-Tie GP69/54-R25 6" x 9" 16-Gauge Gusset Plate - G90 Galvanized, Qty. 25

My Cart:

Add the Essentials

Complete your order with these essentials, compatible with:

Simpson Strong-Tie GP69/54-R25 6" x 9" 16-Gauge Gusset Plate - G90 Galvanized, Qty. 25

My Cart:

-

We are on a mission to expand our national reach—offering more product selection and faster delivery times. So far we’ve made remarkable progress in our expansion efforts, effectively doubling our capacity by adding a new 47,000 sq. ft. warehouse in Simpsonville, South Carolina, in addition to our existing 60,000 sq. ft. facility in Urbana, Iowa.

-

We pride ourselves on delivering a user-friendly, high quality experience online and over the phone. Our knowledgeable team of experts is readily available via phone to assist with product questions and custom pricing inquiries. We’re available Monday thru Friday from 7:00 AM – 5:00 PM CST. We look forward to supporting you on your next job.

-

We partner with trusted manufacturers in the fasteners industry to bring our customers a selection of over 10,000 different products. Fasteners Plus is one of only four Certified Platinum E-Commerce Vendors of Simpson Strong-Tie products, one of the largest suppliers of high-quality structural building products in the world.