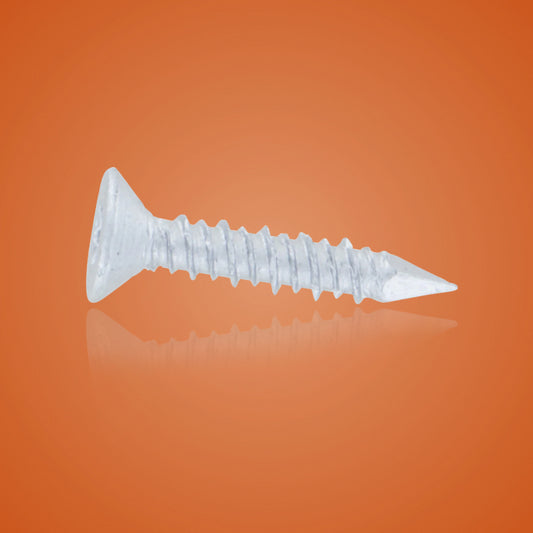

Stainless Steel Concrete Screws

Stainless Steel Concrete Screws Built for Harsh Environments

Stainless steel concrete screws are the ultimate solution for fastening into concrete, brick, and block in environments where corrosion isn’t just possible, it’s guaranteed. Whether you're anchoring into masonry in coastal regions, food-grade facilities, or agricultural buildings, stainless steel offers unmatched longevity, rust resistance, and reliability. These screws eliminate the need for anchors and resist environmental breakdown far better than coated alternatives.

When to Use Stainless Steel Masonry Screws

These screws shine in environments where coated screws would eventually fail:

- Marine/coastal installations (salt exposure)

- Agricultural and livestock buildings (ammonia, moisture)

- Food & beverage processing facilities (frequent washdowns)

- Exterior or partially exposed construction in wet climates

- Critical structural or code-compliant applications

With superior pullout strength and corrosion resistance, stainless steel screws are a long-term investment in the durability of your structure.

Top Stainless Steel Brands at Fasteners Plus

Tapcon Stainless Steel Concrete Screws

Tapcon stainless steel screws combine the brand's trusted anchoring performance with 410 stainless steel strength. They feature a Climaseal® coating over stainless steel for additional protection during installation and early wear-in. These are go-to fasteners for heavy-use commercial and code-compliant projects requiring ICC approval.

Simpson Strong-Tie Titen Stainless Steel

The Titen Turbo™ stainless line is built for smooth driving with minimal torque. These screws use a patented thread design that reduces installation strain, while offering strong holding values in both cracked and uncracked concrete. With a Type 316 stainless option available, Simpson’s lineup meets the needs of chemical processing, wastewater treatment, and extreme outdoor exposure.

Conquest Stainless Concrete Screws

Conquest Fasteners offers professional-grade stainless steel screws at competitive pricing. These are excellent for general exterior or agricultural use and ideal for bulk ordering in high-volume construction settings. Expect consistent threading, easy installation, and dependable hold in CMU, poured concrete, or brick.

How to Install Stainless Steel Concrete Screws

- Use the right bit: Carbide-tipped bits are required. Check product specs for correct pilot hole diameter and depth.

- Pre-clean the hole: Concrete dust affects grip strength, clear out the hole using compressed air or a brush.

- Drive the screw: Use an impact or hammer drill with steady pressure. Stainless steel may require a slower drive speed due to its hardness.

While stainless is tougher than carbon steel, using the correct tools and bit reduces installation fatigue and ensures a tight set.

FAQs About Stainless Steel Masonry Screws

What type of stainless steel are these made from?

Most screws use 410 or 304 stainless. 410 offers higher hardness and strength, while 316 provides top-tier corrosion resistance for highly corrosive environments like coastal or chemical zones.

Are stainless screws magnetic?

410 stainless is magnetic due to its higher carbon content; 316 and 304 are generally non-magnetic. If magnetic properties matter, check the spec sheet before selecting.

Can I install these without a hammer drill?

A hammer drill is strongly recommended. Masonry base materials require proper pilot holes for safe and effective seating. Trying to drill into concrete with a standard drill often leads to overheating or failure.

Do these require washers?

Not usually. Most stainless concrete screws have built-in heads (hex or flat) designed for direct-to-substrate installation. If you're mounting brackets or plate hardware, verify whether a washer is needed for spacing or torque distribution.

Still have more questions? Check out our FAQ on Concrete Screws, or learn the difference between Concrete Screws and Wedge Anchors, or learn about the Types of Concrete Anchors on our blog.

Why Contractors Choose Fasteners Plus

- Industry-Leading Selection: Choose from Tapcon, Simpson, and Conquest in multiple sizes and head types

- Same-Day Shipping: Most orders placed before 4:00pm CST ship same day

- Volume Discounts: Bulk project? Contact us for a custom quote

- Expert Support: Talk to real humans who understand your jobsite needs

FAST SHIPPING, EXPERT SERVICE.

FIND IT FAST. GET IT FAST.

We stock thousands of connectors, fasteners, and more & ship fast to keep your project moving. Need assistance? Contact our experts today.